Electrostatics are used in material separation for example in the recycling process.

When separating plastics, e.g. PET and PVC, the plastic must first be completely disintegrated, there cannot be any material composites present. This is normally achieved through shredding the plastics into pieces of sizes between 2–12 mm.

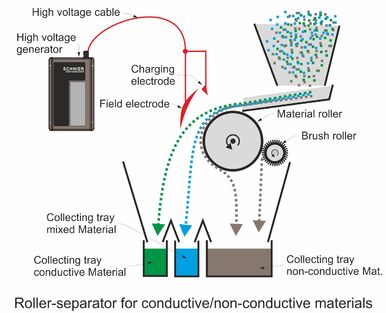

During separation the pieces are first charged, e.g. through friction. PET and PVC have different permittivity (turboelectric properties). If two materials with different permittivity rub against each other, one is then positively charged and the other negatively. In our example the PET is charged positive and the PVC negative.

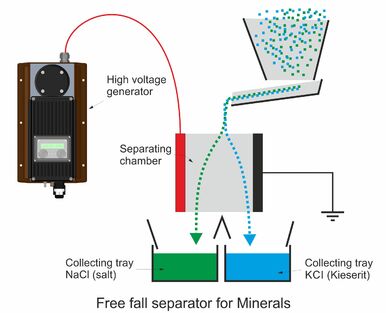

Finally, the charge is applied to the pieces through an electric field. The positively charged pieces are pulled in by the negative electrode. The negatively charged pieces are pushed away by the negative electrode.